Australian Delegation's WFA Factory Visit: Slaughter Equipment & Waste Treatment

This week, WFA Factory hosted an Australian client delegation for talks on customized pig, cattle and sheep slaughter equipment projects, strengthening ties rooted in technical excellence and shared sustainability goals.

Certified Cattle Hide Pulling Machines Under Scrutiny

The delegation focused on WFA’s cattle hide pulling slaughter equipments, built with 304 stainless steel and fitted with CE-certified motors. These key certifications ensure stable, high-efficiency operation, meeting strict global quality and safety standards to the delegation’s approval.

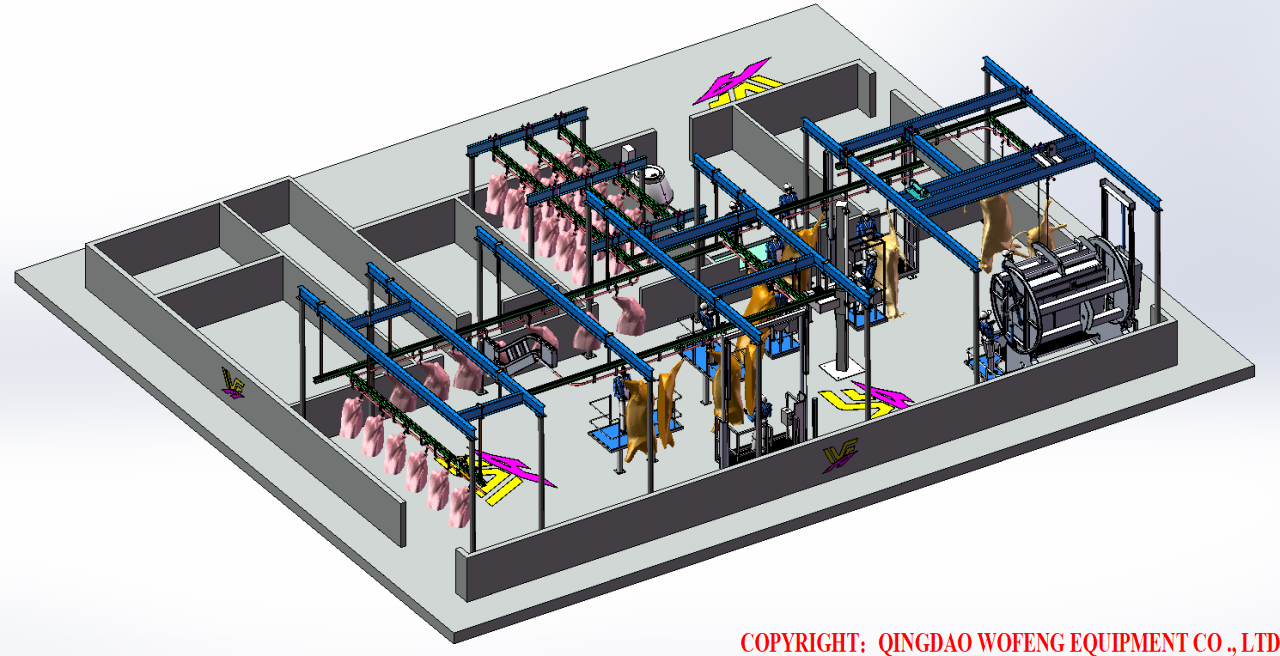

Tailored Track Line Equipment Solutions Win Approval

Both sides reviewed customized multi-species slaughter track line specifications. To meet the client’s needs for staggered slaughter of different animals and combined pig-sheep lines slaughter equipment, WFA engineers proposed optimized track layouts to boost flexibility. The proposals were well-received, enabling further project planning.

Green Waste Treatment Equipment Systems on Display

Post-meeting, WFA’s technical team showcased its sewage and solid waste treatment equipment, demonstrating how the high-quality gear processes slaughterhouse waste to achieve environmental and sustainability goals, in line with the client’s eco-priorities.

Expert Guidance & Workshop Tour Boost Client Satisfaction

WFA’s technical team addressed the delegation’s questions about species-specific slaughter equipment differences and core workflows. The sales team also led a workshop tour, highlighting the manufacturing process of the client’s priority sheep conveyor slaughter equipment. The immersive experience drove high client satisfaction.

The successful visit lays a solid foundation for future collaboration. As a leader in livestock slaughter equipment and waste treatment equipment, WFA remains dedicated to advancing the industry via cutting-edge technology, uncompromising quality and environmental stewardship.