Winter Tenacity, Global Validation: WFA Ulanqab Slaughterhouse Equipment Project Progress Witnessed by Ethiopian Clients

In the heart of winter, Ulanqab, Inner Mongolia, faces temperatures consistently below –20°C—a true test of endurance and expertise. Against this icy backdrop, WFA’s installation team remains unwavering, steadily progressing the equipment installation for a landmark cattle slaughterhouse project. Their disciplined execution in extreme conditions reflects a commitment to excellence that recently drew clients from Ethiopia to witness the project firsthand, resulting in strong endorsement of WFA’s slaughterhouse equipment and service capabilities.

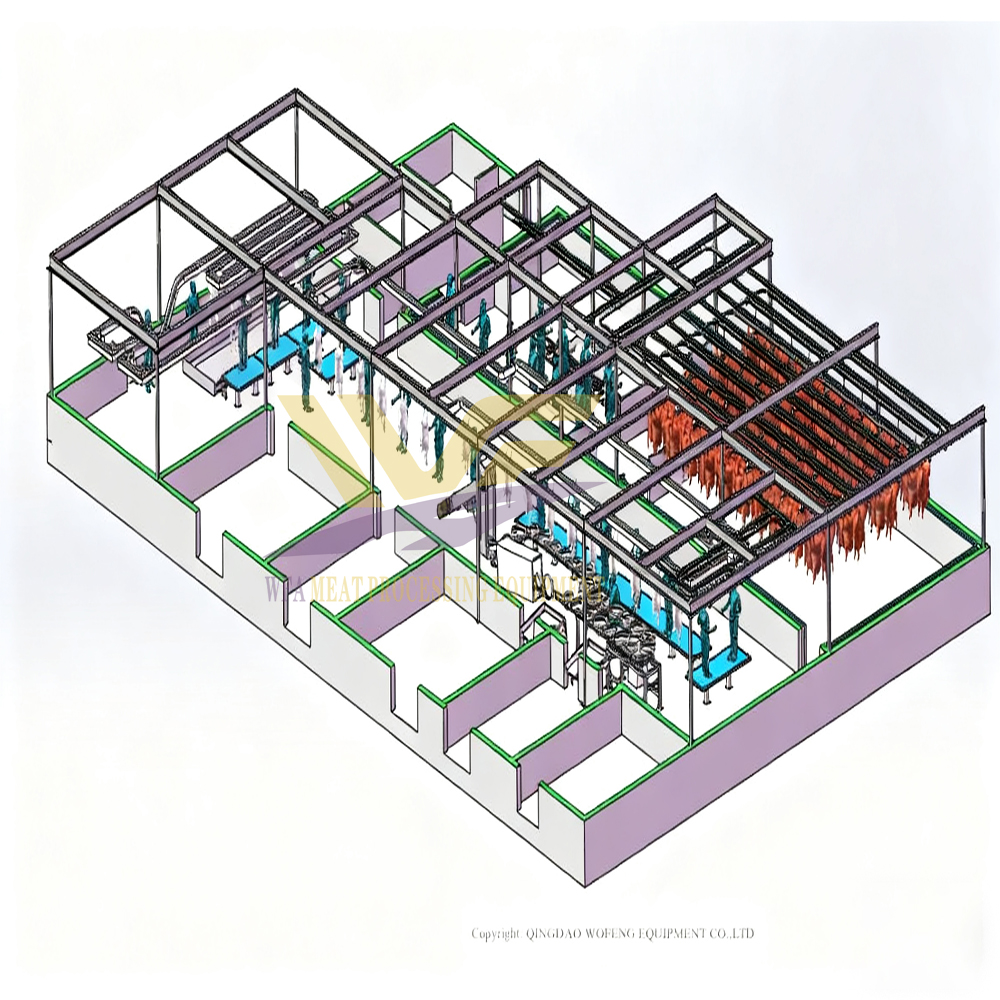

A Vision for Modernized Meat Processing

As a leading slaughterhouse equipment manufacturer and meat processing solutions provider, WFA focuses on client-driven innovation and precision engineering. The Ulanqab project represents a strategic initiative to elevate regional beef processing standards, supporting the industrialization and value-added processing of local agricultural products. To ensure timely delivery despite harsh weather, WFA deployed a specialized winter construction plan, emphasizing cold-temperature sealing, calibration, and systematic slaughterhouse equipment line installation. Every phase—from equipment positioning to pipeline integration—is conducted with rigorous attention to detail, ensuring operational safety, efficiency, and compliance.

Client Engagement: From Inspection to Validation

When the project entered a critical installation stage, Ethiopian clients traveled to the site for a thorough review. Guided by WFA’s project team, they examined slaughtering lines, cutting and deboning equipment, carcass handling systems, ect. WFA technicians detailed slaughterhouse equipment functionalities, operational protocols, and maintenance best practices.

The clients then participated in a trial slaughter operation, observing the seamless automation, hygiene control, and meat quality preservation enabled by WFA’s integrated systems. Post-operation feedback highlighted the equipment’s reliability, precision, and ease of use—strengthening confidence in WFA’s turnkey slaughter plant solutions and project management excellence.

Strengthening Global Partnerships Through Reliable Execution

This project underscores WFA’s capacity to deliver under challenging conditions while maintaining international standards. The successful on-site review not only demonstrates WFA’s technical proficiency but also reinforces its role as a trusted partner in the global meat processing industry.

Committed to a “quality-first, client-centric” approach, WFA continues to support the advancement of livestock processing infrastructure worldwide—driving efficiency, sustainability, and profitability for partners across the supply chain.